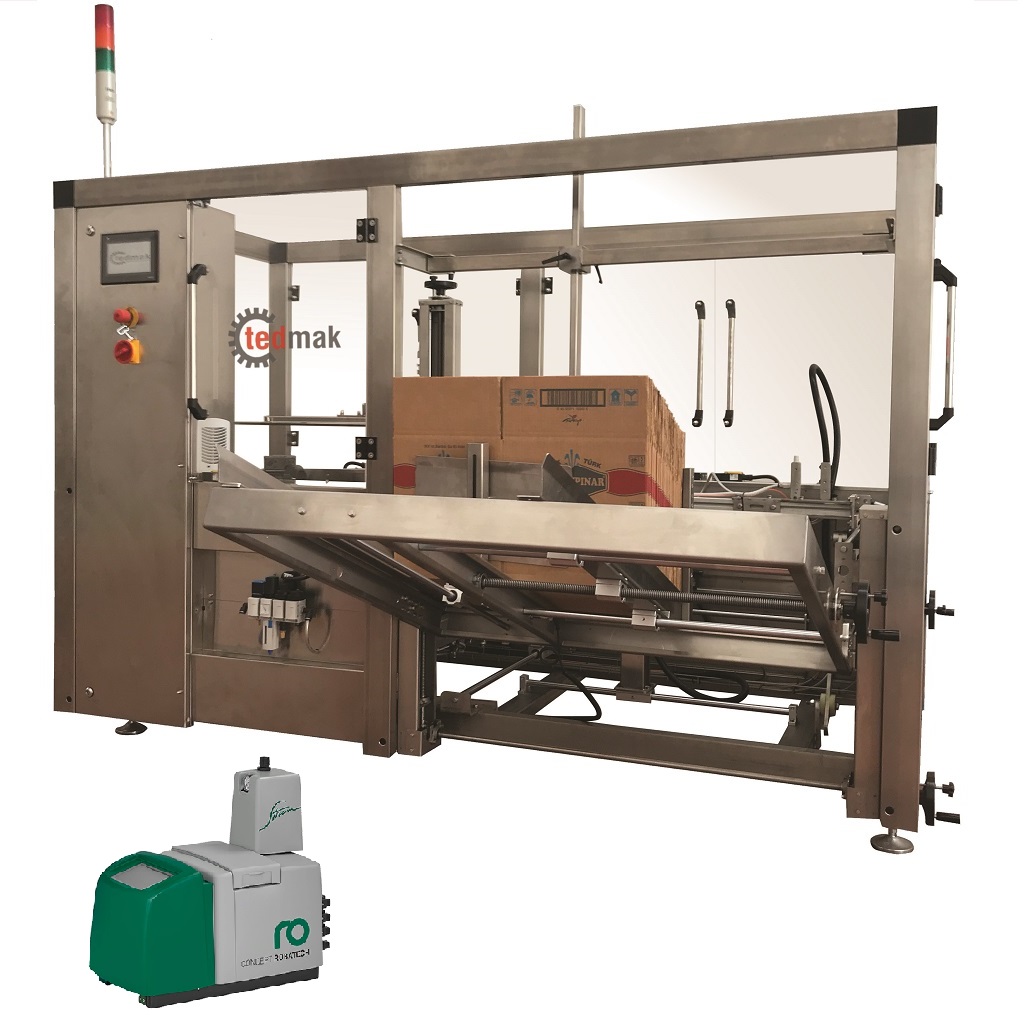

TKH-40-HM Series (Hot-Melt)

TKH-40 Series Automatic Case Erector Machines with Hot-Melt:

- Stainless Steel body and part

- PLC control system (OMRON)

- 7” coloured LCD operator panel (OMRON)

- Timing and speed adjustment on operator panel

- Automatic four-flaps-folder system for bottom flaps

- Pneumatic cylinder driven box opening and pushing system (FESTO)

- Safety doors with mechanical safety switches (SICK)

- Automatic stop when doors are opened

- Box storage for 100 boxes

- Manuel dimension adjustment

- Pneumatic bottom flaps pressing system (FESTO)

- Emergency Stop buttons

- Easy and fast size setting

- Pneumatic system that does not require lubrication (FESTO)

- Two motorized side drive belts (SEW)

- Robatech Hot-Melt glue system

- Bottom glue applicator

- Working with all case and tape types in accordance with international standards

- Minimum maintenance requirement

- CE certificated

Case Dimensions:

TKH-40-HM

| Min. | L: 150mm | W: 150mm | H: 150mm |

| Max. | L: 620mm | W: 420mm | H: 500mm |

Technical Features:

- Electrical connection : 380-400V / 50Hz / 3P+N+PE

- Power : 0,4Kw + 1,8Kw Hot-melt system

- Hot-melt capacity : 5Lt

- Belt speed : 23mt/min.

- Capacity : 10 case/min. (Max.)

- Working height : 600mm (+/-50mm)

- Air connection : 6 Bar

Optional Features:

- Extended box storage

- Casters with brake

Please contact with us for more information.